ISO 13849-1 defines and uses Performance Levels to specify the risk level of a hazard and the required attributes of the Safety Related Parts of the Control System (SRP-CS). The four key attributes of the Performance Levels are shown below.

While performing a risk assessment, machinery risk must be evaluated to determine the minimum required performance level (PLr) that any proposed safety function must meet to effectively reduce the identified risk to an acceptable level. Once the required performance level is determined, an evaluation of the combination of categories, reliability, diagnostics, and a common cause failure analysis is necessary for the system designer to determine a proposed safety function’s achieved performance level (PLa). If the proposed safety function’s achieved performance level (PLa) meets or exceeds the required performance level (PLr), the designer can say with confidence that the risk will be sufficiently reduced. Once the system is built, its function must be verified and validated.

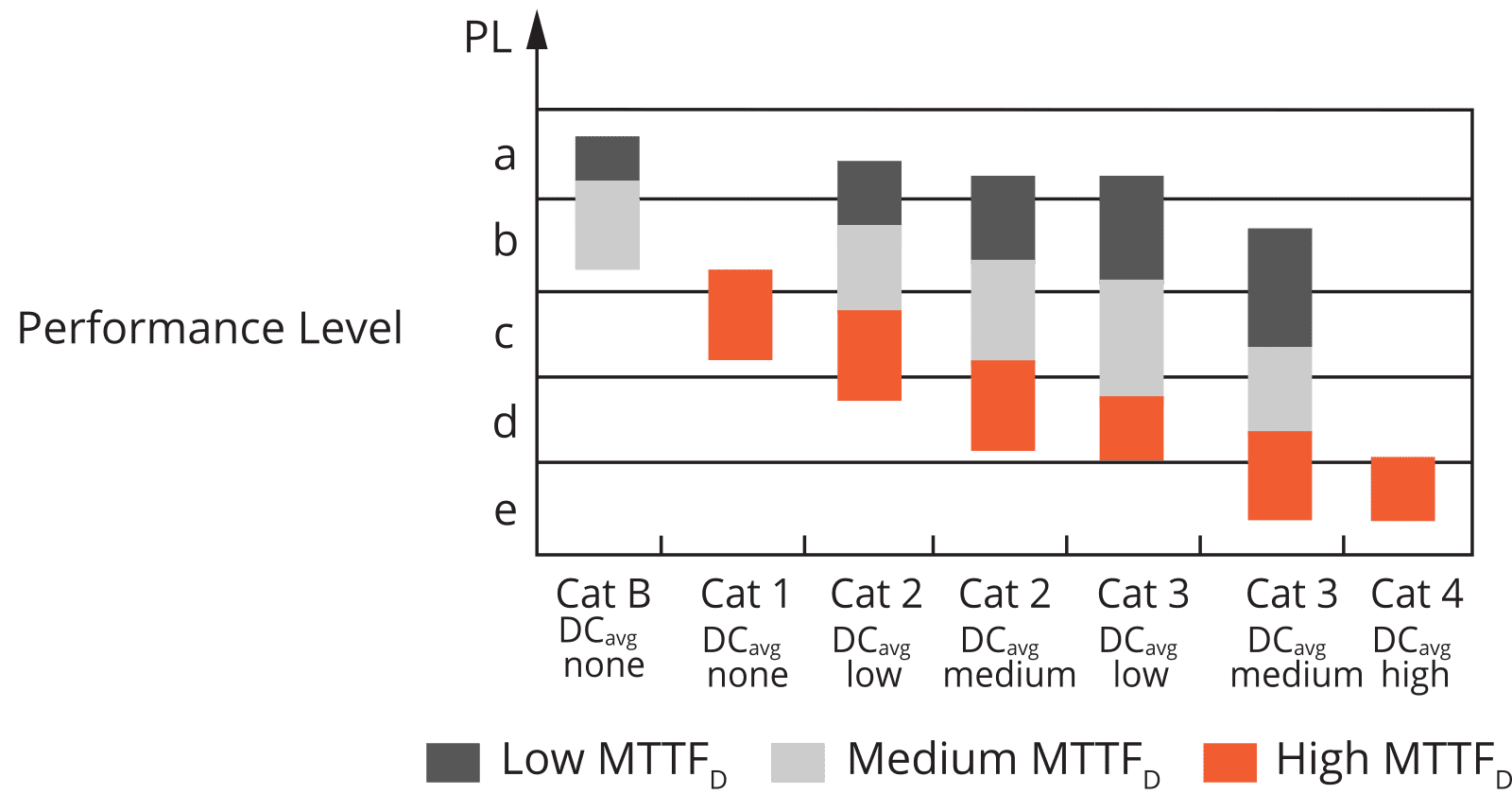

The following shows the relationship between PL and the Category, MTTFD, and DC values for each safety function.