Aluminum Industry Applications

- EnergySaver

- Anode Jacking

- Door Opening

- Breaker/Ore Feed

- Overhead Crane

Steel Industry Applications

- Furnaces

- Hot Rolling Mill

- Annealing

- Sheering

- Energy Saving

- Steel Processing

- Cold Rolling Mill

- Galvanizing

- Baghouse

- Continuous Casting

- Picking

- Coating

- Water Treatment

Industry Solutions - Poppet Valves

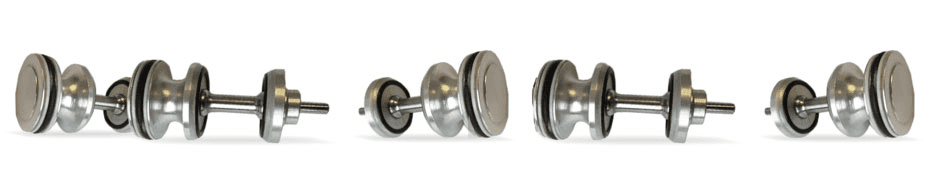

ROSS poppet valves are the product of choice for the Aluminum and Steel Industries. With its proven reliability and performance plus consistent switching times it has proven itself over many decades in this challenging and unforgiving environment. Its internal construction has been carefully calculated to produce strong shifting and sealing forces in each direction which results in a design which ensures high speed, repeatability and high shifting forces over the life of the valve.

ROSS poppet valves have positive sealing with no sliding action to prevent damage and wear. They are also self-cleaning and dirt tolerant thanks to the smallest flow-through area across the poppet’s seal and seat which produces a high-enough velocity to blow out all dirt and foreign matter. Plus, the valve is self-compensating for wear by automatically changing stroke length due to height changes in the valve seal from burnishing. These valves are designed for repeatability, high-temperature service, high speed, and high-shift consistency over the life of the valve.

Browse Our CatalogFeatured Product

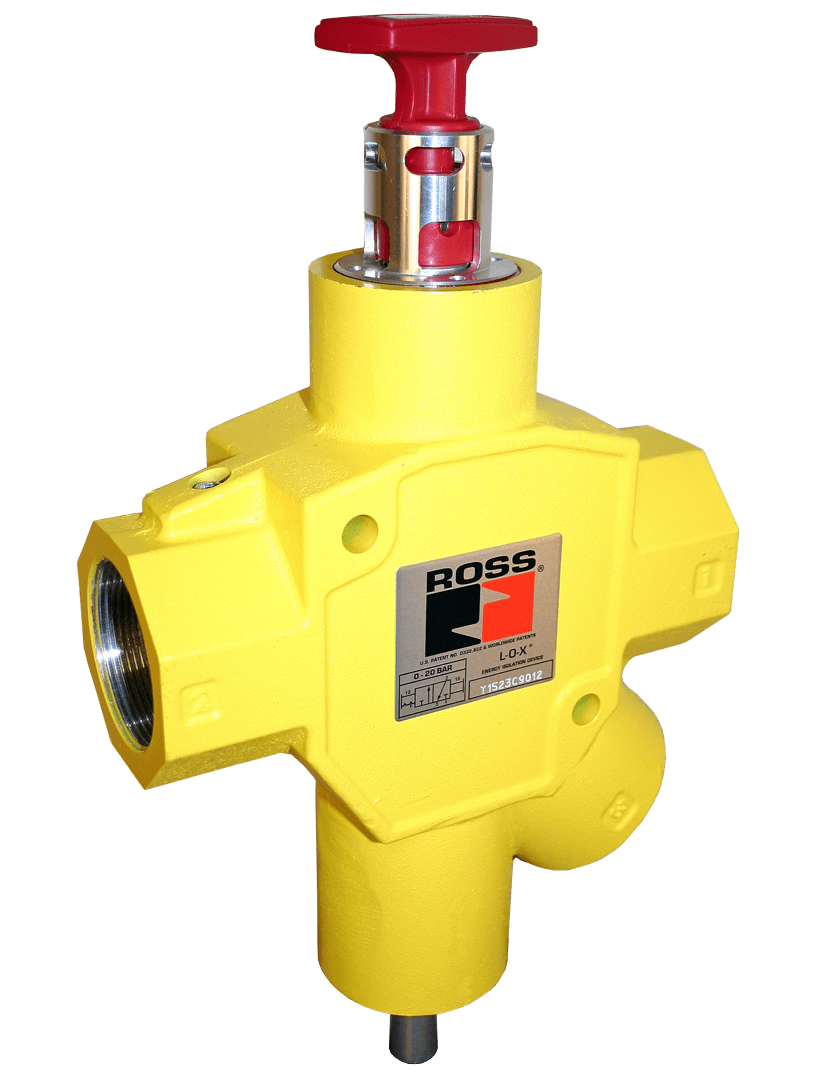

15 Series High Capacity Manual Lockout L-O-X® Valve

Following any FRL components, an energy isolation valve is usually the first valve in the line supplying compressed air to equipment. The energy isolation valve should provide a quick means of shutting off the supply of air and exhausting the downstream lines. The ROSS High Capacity Manual Lockout L-O-X® valve is offered in either 1-1/2” & 2” ports. It’s yellow body and large red operating handle allow high visibility. All 15 Series Lockout Valves include an integrated sensing port for pressure verification where a visual pop-up indicator or pressure switch can be installed.

The controlling spool of the valve employs seals made of very low-friction material. These seals enable the L-O-X® spool to shift smoothly and easily even after being on standby for a long period of time. The large exhaust port enables rapid release of line pressure and is threaded for the installation of a silencer or a line for remote exhausting.

ROSS/FLEX® – Tailoring Standard Products to Your Specific Applications

ROSS/FLEX®

Using the customer’s expertise and intrinsic knowledge of the smelter application, together with ROSS engineering’s capability to quickly design/manufacture a solution using ROSS' proven Poppet internals, opens the door to painless continuous improvement (cost reduction, improved performance, increased uptime, improved safety, etc.).

Get StartedROSS® Systems

ROSS is a trusted source for systems and panels for existing or new designs. ROSS will build and test systems and panels to your exact specifications using superior materials and proven expertise and can offer on-site testing and installation assistance.

Get StartedROSS Controls® - Safety Specialists

Achieve compliance (ISO, EN, ANSI, CSA and OSHA). ROSS employs a team of Global Safety Specialists with vast experience and knowledge of the applicable global standards for fluid power applications. A well-designed Safety circuit will reduce risk, improve productivity and ultimately increase your bottom-line. Safety should be the cornerstone of any loss prevention program.

Learn MoreContact Our Team

ROSS employs a powerful team of experts with vast experience in fluid power able to help you find a solution for your safety goals. Whether it be a custom solution, a current product, application, or safety course, ROSS is here to provide just what you need with your business specifications in mind.